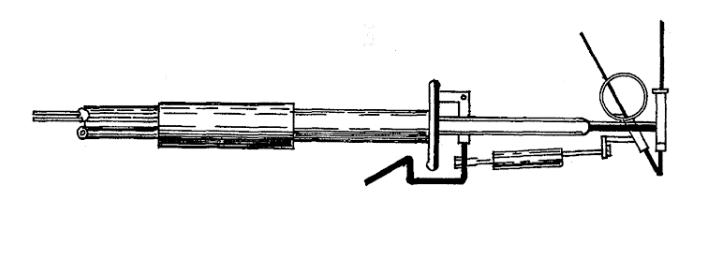

Atomic hydrogen welding is an arc welding process that makes use of hydrogen gas to surround and transfer heat from an arc to the base metal. An atomic hydrogen welding torch contains two tungsten metal electrodes that form the electric arc. Hydrogen gas (H2) is used as a shielding gas, which dissociates into its elementary form (H+) as it passes through the arc.

The difference between atomic hydrogen welding and MMA welding or TIG welding is that in the latter cases, the arc is formed between the electrode and the base metal.

The tungsten electrodes are non-consumable, and the distance between them can be altered to control the heat produced at the arc. An a.c transformer typically supplies the required current. External filler metal may or may not be required depending on the thickness of base metal.

The process was invented by American Chemist and Physicist Irving Langmuir in the course of his research on atomic hydrogen at the beginning of the 20th century.

The amount of heat absorbed by the hydrogen gas (H2) is equal to the bond energy of the two hydrogen molecules.

Once the hydrogen molecules hit the surface of the base metal, the reverse reaction occurs and the heat previously absorbed to break the bonds is released to the base metal. The chemical reaction involved provides for a very efficient transfer of heat from the arc to the base metal.

In addition to its involvement in heat transfer, hydrogen also serves as a shielding gas that protects the weld pool from atmospheric contamination. For example, any oxygen near the weld pool combines with hydrogen to form water that escapes as steam. If oxygen is not kept away from the weld pool, the formation of metal oxide is inevitable.

The temperatures achieved by this welding process are much higher than oxy-acetylene gas welding, with temperatures going up to 4200°C. The flow of hydrogen around the electrode also serves to cool and prevent evaporation of the tungsten.

The atomic hydrogen arc welding process is very versatile and can be used to weld to almost any metal. It is especially useful in welding light gauge metals, ferrous alloys, and most non-ferrous alloys. It can also be used for any process requiring a precision weld, for example correcting machining errors.